On the planet of electronics and modern technology, the relevance of printed circuit card (PCBs) can not be overstated. These elaborate components create the backbone of virtually every electronic tool, from computer systems and mobile phones to family appliances and clinical devices. A PCB, frequently described as a circuit card, provides the crucial framework for connecting numerous electronic components via conductive tracks etched onto non-conductive substratums. Amongst the many sorts of PCBs, the rigid-flex circuit boards stand out as an exceptional technology. These are hybrid boards that combine the finest features of flexible and rigid PCBs, enabling dynamic designs that can turn and flex without sacrificing structural stability. This versatility makes rigid-flex circuits especially appealing for applications where area is restricted, such as in smart phones and wearables.

The production of PCBs, particularly in high-density interconnect (HDI) arrangements, has advanced as the demand for smaller sized, faster, and much more reliable electronics increases. HDI PCBs integrate finer lines and rooms, as well as smaller vias, which enable for better element density.

Joint endeavors with printed circuit manufacturers are critical in guaranteeing that PCB layouts change smoothly from conceptual phases to actual items. These manufacturers concentrate on various elements, consisting of PCB assembly and fabrication. They make use of materials like FR-4, a flame-retardant epoxy resin, which is commonly related to for its equilibrium of efficiency and cost-effectiveness. In the world of high-performance applications, variants such as Rogers material, Megtron 6, and Megtron 7 are regularly made use of for their superior dielectric residential properties and high-frequency efficiency. Printed circuit board assembly (PCBA) comes to be a crucial step in the process where different components are soldered onto the PCB in specific setups to make sure ideal operation.

Quick turn-around PCB prototyping services have obtained popularity as organizations aim to bring their products to market quickly. This agile manufacturing strategy permits companies to examine and verify their styles prior to devoting to complete production runs. Such prototyping is crucial in decreasing time-to-market and enables for repetitive renovations based upon preliminary testing outcomes. Suppliers supply flexible alternatives for both high-volume and low-volume orders to fit varied manufacturing demands. With the enhancing schedule of fast-turn PCB services, the barriers to prototype advancement have actually been significantly reduced, making it possible for a setting of development.

Flexible printed circuit boards (FPCBs) are another impressive classification that has amassed interest due to their special abilities. These boards are developed to be ultra-thin and light-weight, providing the ability to flex, fold up, or spin without compromising efficiency.

Thermal management, for instance, plays a vital duty in PCB design, particularly in electronic items that run under high lots. Designers have to consider products with good thermal conductivity, such as heavy copper PCBs, which help dissipate heat efficiently.

The understanding check here of printed circuit click here card design is essential for designers and item designers. Finding out about different elements such as circuit card assembly, which consists of the process of soldering elements onto a PCB, can considerably impact completion item's high quality. Reliable design techniques make sure that electrical pathways are optimized and that the total format reduces interference, thereby boosting life expectancies and performance. Additionally, making use of devices and software application designed for PCB format and simulation can substantially improve the design process, allowing makers to swiftly alter prototypes based upon testing outcomes.

Variants in PCB kinds such as 2-layer, 4-layer, and multi-layer boards are each fit to certain applications based on their intricacy and the number of components that require to be incorporated. Four-layer PCBs supply raised routing abilities, critical for more advanced electronics. These boards assist in taking care of signal integrity and offer adequate room to route traces better, guaranteeing even more trusted performance in whatever from mobile phones to complicated commercial tools.

Contract PCB assembly services have actually become an important resource for companies lacking the internal capabilities to deal with complicated assembly processes. These services typically include comprehensive support varying from design appointment to major production, offering businesses with the flexibility they require to fulfill differing demands. By partnering with recognized manufacturers, companies can leverage proficiency in areas such as HDI formats, microvias, and multilayer PCBs, consequently broadening their product offerings without investing heavily in tools and labor.

Selecting the best materials for PCB production is crucial, and considerations often consist of the ecological standards relevant to their usage, including UL rankings, such as 94V-0, which relates to terminate retardancy. Manufacturers require to remain informed about conformity guidelines to guarantee that their items satisfy safety standards while also performing ideally in their designated application environments.

The assimilation of radio frequency (RF) modern technology into PCBs is an additional area seeing increased significance, particularly with the increase of wireless communication tools. RF PCBs should be meticulously developed, with factors to consider for insusceptibility control and reduced signal loss as a result of the high frequencies included. This field of expertise requires understanding of RF circuit design and might involve in-depth electro-magnetic simulations as engineers work to accomplish optimum functionality in small kinds.

As technology remains to develop, manufacturers are progressively adopting automation and progressed fabrication procedures to improve performance. Technologies such as automated optical examination (AOI) and surface mount technology (SMT) are now conventional methods, permitting for high-speed assembly and consistent quality assurance. Advancements in PCB manufacturing additionally include brand-new products and techniques, such as using embedded innovation where components are ingrained straight within the layers of the PCB, better saving space and improving performance.

Finally, the printed circuit card market constantly adapts to altering demands and technological advancements, reflecting the dynamic landscape of electronics. Whether through PCBA, flexible circuits, or fast-turn prototypes, the processes, materials, and read more designs connected with PCBs are essential fit the future of electronic gadgets. Manufacturers that remain at the forefront of these innovations not just boost their affordable edge yet additionally allow the growth and growth of sophisticated innovations that define modern-day life. With the ever-increasing complexity of circuits and the demand for effective, high-performance solutions, the PCB sector stays a cornerstone of technical progress, driving the method we interact with gadgets and ultimately linking our digital and physical globes.

Alfonso Ribeiro Then & Now!

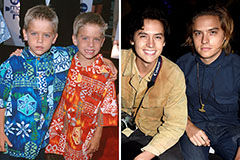

Alfonso Ribeiro Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Nancy Kerrigan Then & Now!

Nancy Kerrigan Then & Now! Bo Derek Then & Now!

Bo Derek Then & Now! Morgan Fairchild Then & Now!

Morgan Fairchild Then & Now!